China professional FM1325-4axis AC 220V/380V woodworking machine cnc router 4 axis atc

1.Brief Introduce

With hard steel structure, the machine is fit for hard wood working, like cutting and engraving on Rosewood for furniture, indoor decoration, and it is qualified for mass- producing of furniture with the Vacuum holding way and dust collector.

We use top quality components for the machine, such as HSD spindle, and the spindle can rotate 180 degree, Delta Inverter, Becker Vacuum pump, Hiwin linear, Syntec EZ-4M control system and so on, to keep the machine in the best condition even after working for many years.

2.Top Quality Components

1). The machine’s body is strong, high-precision, reliable and durable.

2). Imported high-precision ball screw, which moving smoothly, to ensure the machine’s high precision.

3). Well-known HSD Auto Tools Changer spindle, strong cutting ability, low noise, to ensure the machine working for long time.

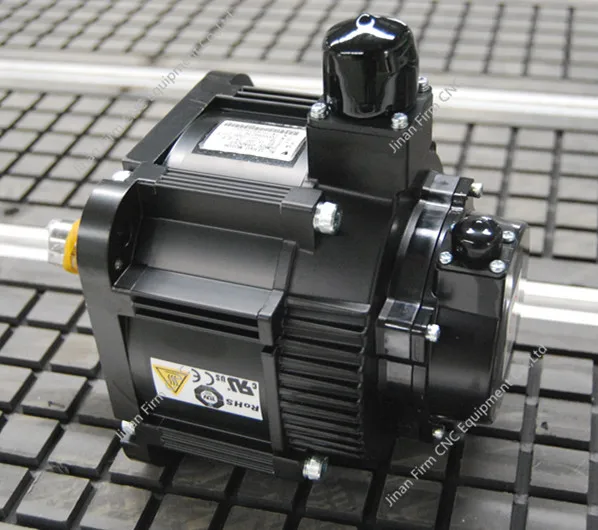

4). High-performance driven motor to ensure the machine’s high speed and accuracy.

5). Breakpoint specific memory to keep the carving status when power off, processing time forecast and other functions in case of the accidental power outages

6). Auto lubrication system and separated control system, easy to operate.

7). Perfect design, top quality accessories, to minimize the machine’s failure rate.

3.Performance parameter

| Number | Description | Parameter |

| 1 | X,Y,Z Working Area | 1300x2500x400mm |

| 2 | Table Size | 1450×2940mm |

| 3 | X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

| 4 | X,Y,Z Repositioning Accuracy: | ±0.03mm |

| 5 | Table Surface | Vacuum and T-slot Combined (Option: T-slot Table) |

| 6 | Frame | Big Steel Tube Structure |

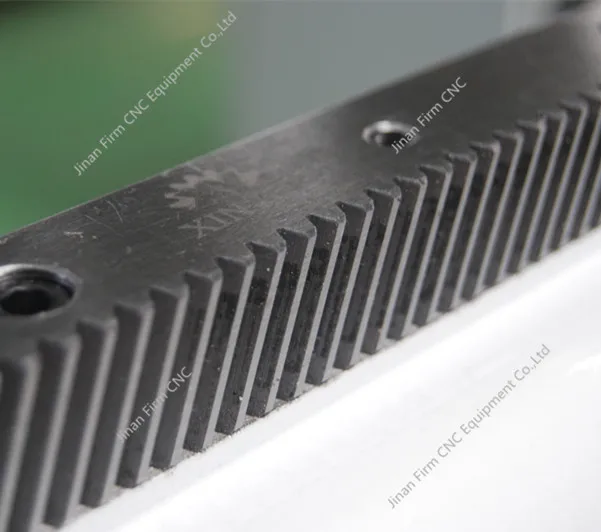

| 7 | X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| 8 | Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| 9 | Max. Power Consumption | (Without Spindle) 4.5Kw |

| 10 | Max. Rapid Travel Rate | 40000mm/min |

| 11 | Max. Working Speed | 30000mm/min |

| 12 | Spindle Power | 9.0KW |

| 13 | Spindle Speed | 0-24000RPM |

| 14 | Drive Motors | 850W Yaskawa Motors |

| 15 | Working Voltage | AC380V/50/60Hz,3PH (Option: 220V)) |

| 16 | Command Language | G Code |

| 17 | Operating System | Syntec Control System |

| 18 | Computer Interface | USB |

| 19 | Flash Memory | 512M |

| 20 | Collet | ER32 |

| 21 | X,Y Resolution | <0.03mm |

| 22 | Software Compatibility | Type3/UcancameV9 software (Option: Artcam software) |

| 23 | Running Environment Temperature | 0 - 45 Centigrade |

| 24 | Relative Humidity | 30% - 75% |

| 25 | Packing Size | 3300X2100X2300mm |

| 26 | N.W. | 1750KG |

| 27 | G.W. | 2150KG |

| 28 | Optional Parts | Dust Collector/ Dust Hoods for three Axis |

| Vacuum Pump | ||

| Rotary System | ||

| Mist-cooling System | ||

| Delta/ Panasonic Servo Motors | ||

| Colombo Spindle |

4.Spare parts of cnc wood machine router

9.0 KW Italy Air cooling spindle

Syntec control system

850W Jaanese Yaskawa Servo motor

Helical rack

5.Samples of cnc wood machine router

6.Guarantee & After Sales Service of cnc wood machine router

1). The machine is guaranteed for 2 years.

2). Technical support by phone, email or MSN around the clock.3). Friendly English version manual and operation video CD disk.

Our QC team of cnc wood machine router

A QC team with professional and technical personnel. To ensure 100% cnc router machine checking.

Material: Strictly control of material using, meet international requested standards.

Semi-finished products inspection: Product inspection before 100% finished.

Production line test: With work team or data engineer who will inspect machines and lines at fixed period.

Finished Product Inspection: Quality and property test beforecnc router machine are packed and loaded.

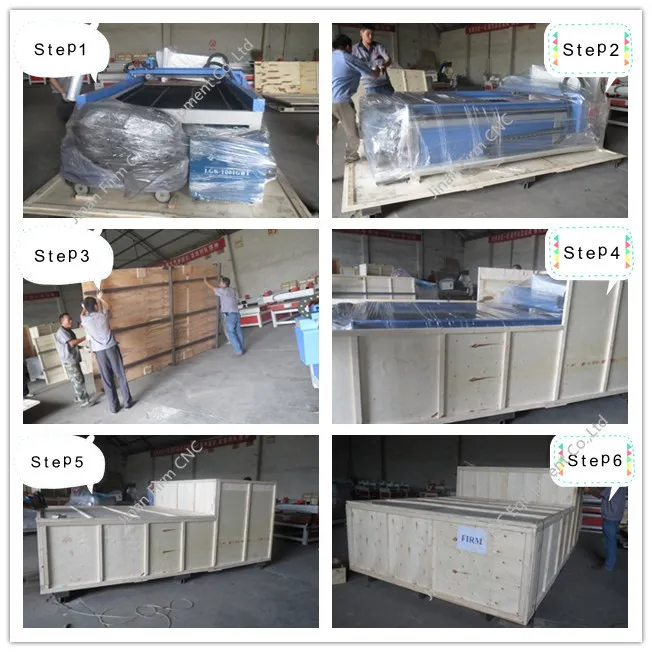

7.Packaging & Shipping of cnc wood machine router

Water-proof plastic film package with foam protection.

Solid Seaworthy Wood Box Package with Steel Belt.

Save space as much as possible for container loading.

8.Advantage of Firmcnc of cnc wood machine router

♦ Professional testing&processing technology

1)The gap between the welded steel is only 100mm, which avoid the machine being out of shape.(Others usually 500mm)

2) The testing of Ball screw, to ensure the parallelism

3) The testing of Frame, to ensure the parallelism between the square rail and the frame

4) The testing of Spindle, to ensure its accuracy

5) The testing of linear guide rail, to ensure its precision

Q1: How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client s specific requirements, it would be 15 to 30 days.

Q2: How about the payment terms?

30% T/T for deposit, 70%T/T paid before shipping.

T/T, West Union, Paypal

Q3: Do You Arrange Shipment For The Machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

Q4: How about Guarantee & After Sales Service?

1) The machine guarantee is 12 months.

2) 24 hours technical support by phone, email or msn, skype etc.

Q5: If some problems happened to this machine during warranty period,what should i do?

We will supply free parts in machine warranty period if machine have some problem.While we also supply free after-service forever, so any doubts,just let us know, we will give you solutions in 24 hours.

Q6: What is the MOQ?

MOQ for our products is 1 set machine,we could send it to your country port if you tell detail information about your country port.

Jinan FirmCNC Equipment Co.,Ltd

Tel:+86-0531-69986330

Fax:+86-0531-69986330

Mob:+86-18560216660

Email:admin@firmcnc.com

Website:www.firmcnc.com

Address:A505,Jingliu Road,Huaiyin District,Jinan,Shandong,China